The right manufacturer for you, send your inquiry to us! | [email protected]

Welding service

Professional, high quality welding service is vital to our economy. It is often said that over 50% of the gross national product of our products are related to welding in one way or another. Welding ranks high among industrial processes and involves more sciences and variables than those involved in any other industrial process.

Nearly everything we use in our daily life is welded or made by equipment that is welded. Welders help build metal products from coffeepots to skyscrapers. They help build space vehicles and millions of other products ranging from oil drilling rigs to automobiles. In construction, welders are virtually rebuilding the world, extending subways, building bridges, and helping to improve the environment by building pollution control devices. The use of welding is practically unlimited. There is no lack of variety of the type of work that is done.

Click here to check our welding products.

TIG & MIG welding on metal products for you

What products we do by welding services?

TIG welding

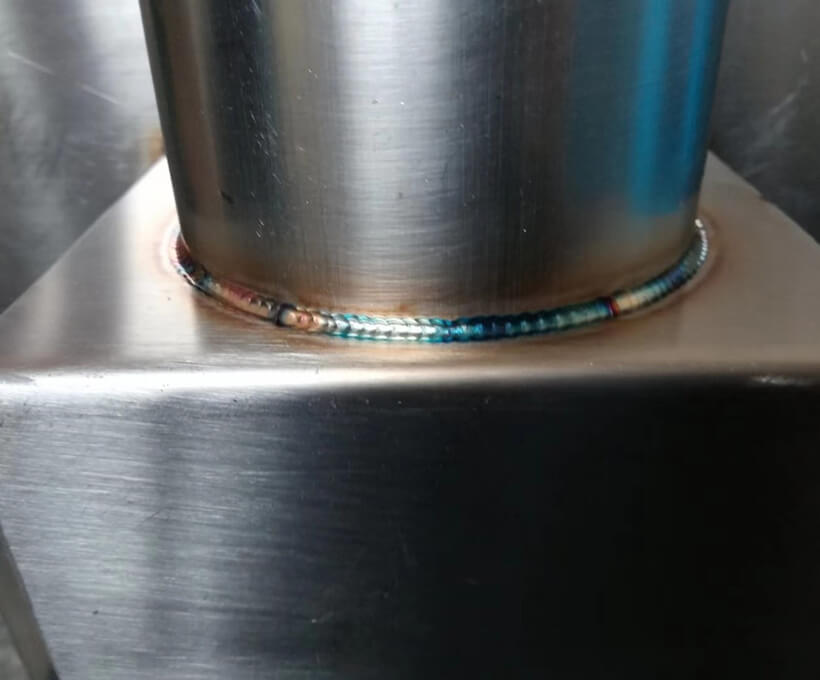

1. TIG (Tungsten Inert Gas) welding is a welding method using argon as the shielding gas and tungsten as the electrode. And the TIG welding wire is for in straight strips of a certain length. Depending on the operation, there are three types of welding: manual, semi-automatic, and automatic. And the main application is the welding of workpieces with thin and medium thickness. And it can be used as root weld channels in thicker cross-sections. Since no flux is used, it reduces the chance of slagging and improves the weld’s quality. TIG has been used in the aerospace industry where high-quality welding is required.

MIG welding

2. MIG (Metal Inert Gas) welding is a melting electrode arc welding method that uses inert gases such as Ar as the main shielding gas, including pure Ar or Ar gas mixed with a small amount of active gas. This welding method uses the arc that burns between the continuously fed & melted wire and the workpiece as the heat source. It uses the gas emitted from the torch nozzle to protect this arc for welding. Mainly, MIG welding for to stainless steel, aluminum, magnesium, copper, titanium, pick and nickel alloys.

MAG (Metal Active Gas) welding is a welding process in which a small amount of oxidizing gas (oxygen, carbon dioxide or a mixture of these gases), adding to argon gas to form a mixed gas shield. The main advantage of MAG welding is that it can readily apply to in various positions, and it also has the advantages of faster welding speed and higher deposition rate. MAG welding is mainly for the welding of ferrous metals such as carbon steel, alloy steel, and it is also widely apply to stainless steel welding.

Why choose Infengde?

Based on more than 10 years of practice, and overall technical support from our rich-experienced engineering team, Infengde can provide customers with the most optimal solution to choose the proper manufacturing process and material, which expects to save a more-than-10% cost for the project. Meanwhile, based on the service team’s quick response, we are always there whenever you need us, saving time for both of us.

As a custom metal parts manufacturer in China, Infengde’s unique advantages include:

1. High quality – Strictly according to the quality management policy. Also have built up a perfect quality control system from inspection to final delivery of the products.

2. Availability of diverse materials – Infengde has a supplier management system that can always pick up the optimum provider for different materials. And we can meet the requirements from prototyping to mass production.

3. Combination of experience and advanced technology. A technology supporting team that includes both hands-on production engineers coming from the workshop and professional design engineers from modern universities;

4. One-stop manufacturing services – In addition to the Welding fabrication lines. Infengde also has other metal manufacturing processes, including sheet metal stamping, metal casting, drop forging, CNC Machining, Powder Metallurgy, and surface treatment. And that’s why we can meet customers’ demands for a one-stop service of manufacturing a whole set of their products.

We are a OEM / ODM Production Service company.

At Infengde, we are very proud to offer a wide range of services including a variety of welding services. Also, service and quality are how we have grown and it is why our customers choose to come back to us time and time again. Whether you have a small part or one that incorporates all that we offer, we hope you will consider Infengde. We accept custom design metal parts and also can assist customers on making engineering drawings. Infengde can make samples for approval before mass production for your steel mandrel bends. Visit our facebook page or linkedin page for more about us. Contact us via email [email protected] for any futher information.