The right manufacturer for you, send your inquiry to us! | [email protected]

Stamping process

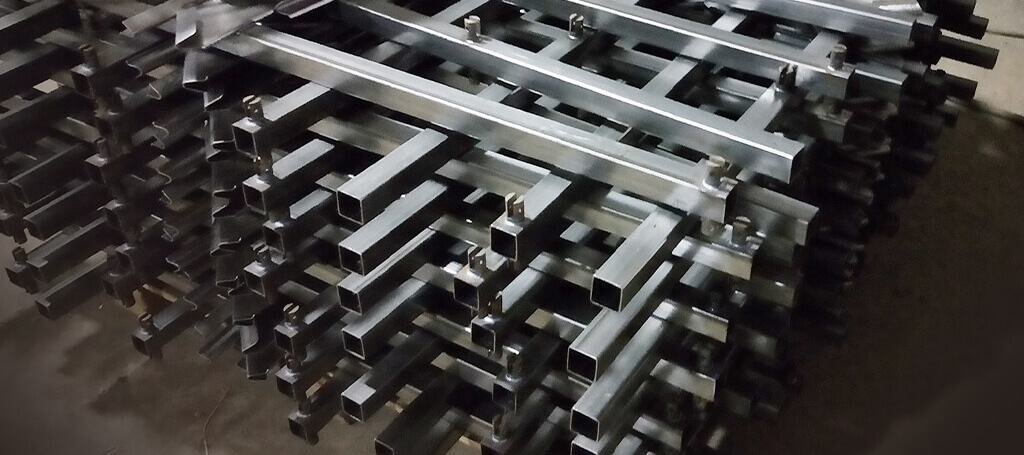

With the capability to perform various of sheet metal fabrication, such as laser cutting, bending, welding, threading & chamfering, deburring, riveting, and other processes in-house, and with a complete supply chain to handle a wide variety of surface finishes, we’re well positioned as a sheet metal supplier to meet the needs of our customers for both components and assemblies.

Click here to see our sheet metals with welding products.

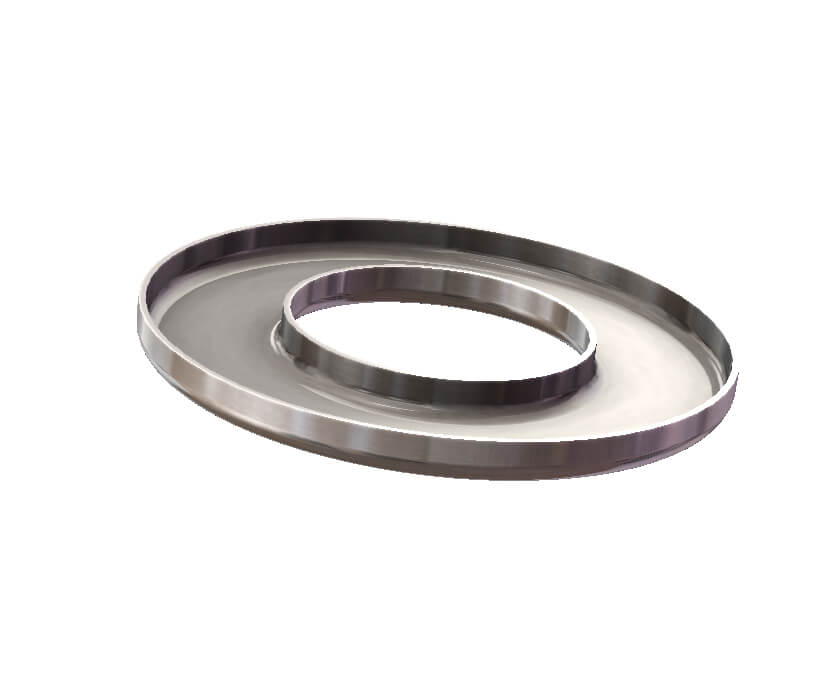

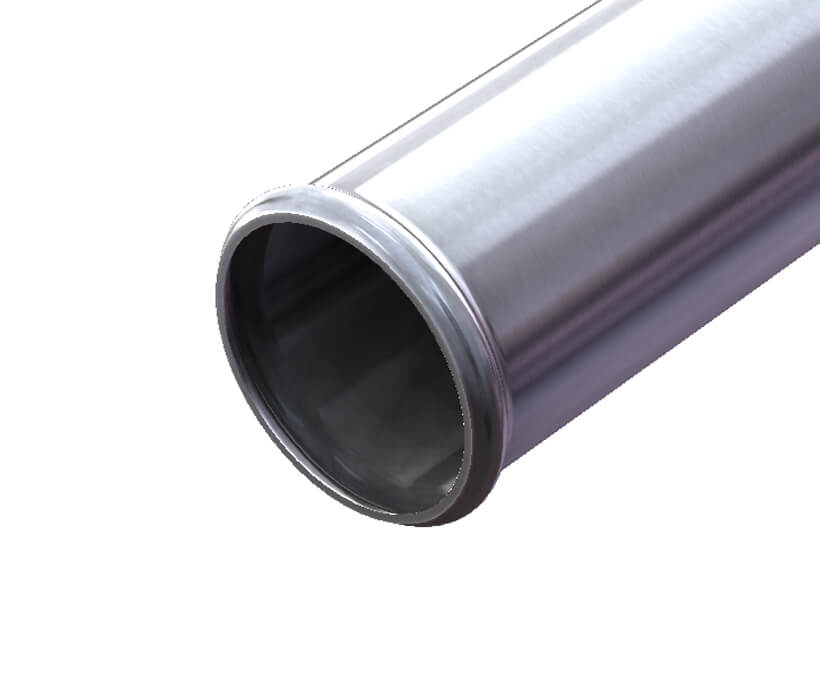

What products we do by stamping?

Why choose Infengde?

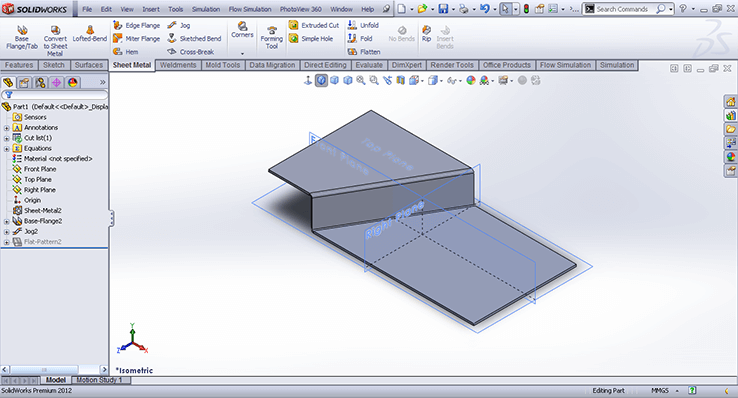

We help you fine-tune your product design through Solidworks, thus to ensures your parts can be manufactured accurately, efficiently, and at a quality that matches your specifications.

We also have the capabilities to manufacture complex, high precision parts using steel, aluminum and stainless steel, because we also do assembly and other complex production services besides simple fabrication.

Our ERP enables us to manage in-house manufacturing of finished products with multiple SKUs. Our most complex product manufactured to date is made of 320 components.

As we are designed to manufacturing support to full scale mass production for sheet metal products. We support secondary operation such as welding, riveting and surface finishings and also provide sub-assembly service or deliver finished products.

We are a OEM / ODM Production Service company.

At Infengde, we are not only provide simple fabricated products, we also offer a wide range of assembly services and welding services to our customers. Also, service and quality are how we have grown and it is why our customers choose to come back to us time and time again. Whether you have a small part or one that incorporates all that we offer, we hope you will consider Infengde. We accept custom design metal parts and also can assist customers on making engineering drawings. We can make samples for approval before mass production for your steel mandrel bends. Visit our facebook page or linkedin page for more about us. Contact us via email [email protected] for any futher information.