The right manufacturer for you, send your inquiry to us! | [email protected]

We are mandrel bending china manufacturer in Ningbo City, Zhejiang province

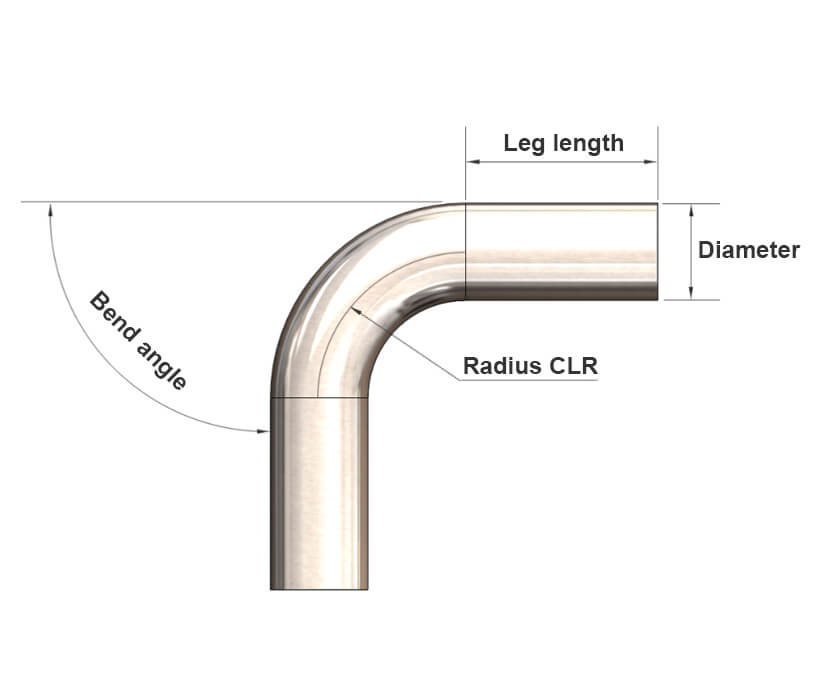

Infengde is a mandrel bending china manufacturer which supplies professional mandrel bending services to our customers. When people buy mandrel bends from a supplier, what key points we need to know about to better communicate?

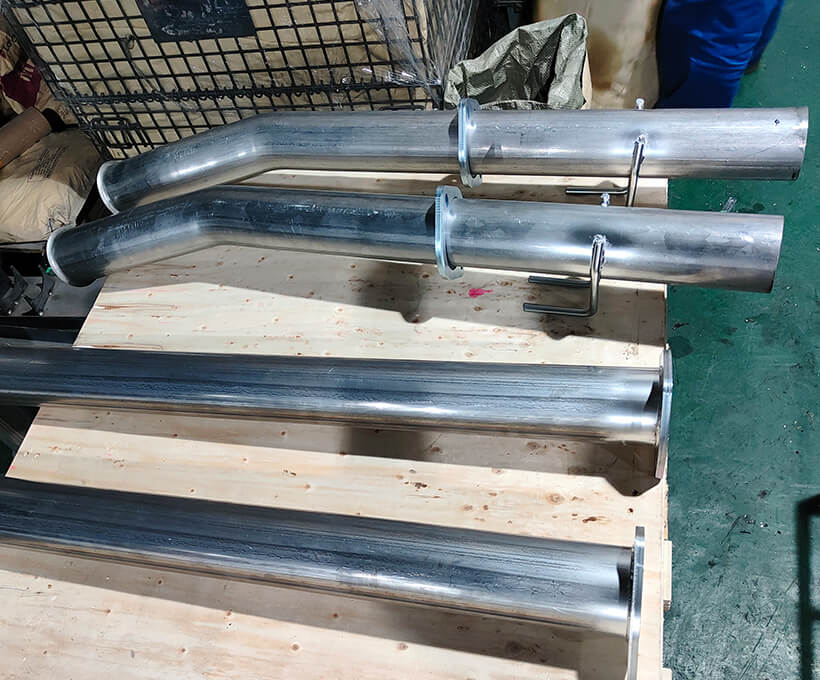

As a professional mandrel bending china manufacturer, what products exactly we can do for you?

- Material: Mild steel, stainless steel, aluminized steel, aluminum, copper, brass…etc

- Diameter: Max 5 inch, equals 127mm

- Wall thickness: Max 5mm

- Bend angle: 0 – 180 degree

- Bend radius: Min 1.0D

- Leg length: Max 2000mm

- Surface treatment: Polishing, brushing, powder coating, painting, anodizing, electrotitic coating, electrical polishing…etc

- Packing methods: Carton box, pallet, wood crate, wood box, custom packing method

There are some necessary components For Mandrel Bends

The mandrel, which is the key component of tooling, that is the key part provides support to the inside of the tube. Its primary function is to prevent the tube from buckling and necking, and there are many different variations of mandrels exist.

The bend die is the primary tool forming the tube to produce the desired bend radius. This is the form against which the tube is clamped and then drawn around to produce the bend. The essential specifications of a bend die are the outside diameter and the bend radius of the tube to be bent.

The wiper die keeps the tube from wrinkling during the bending process. A wiper die is very important if the tube’s resistance to compression is high.

A clamp die which is an important part, that is the part makes good bending or bad bending, it clamps the tubing material against the bend die as it rotates to form the bend. There are two specifications of primary importance in a clamp die, Length and cavity texture, which are related to each other. If the clamp is short, then the cavity surface will be rough because it must be to maintain the force of the grip on the tube. Serrations, knurling, and carbide impregnation roughen the cavity surface which improves the clamp die’s grip upon the tube.

Infengde accept custom design metal parts and also can assist customers on making engineering drawings. We can make samples for approval before mass production of mandrel bending products.

Visit the facebook page or Linkedin page for more about us, also, you can contact us via email [email protected] for any futher information.